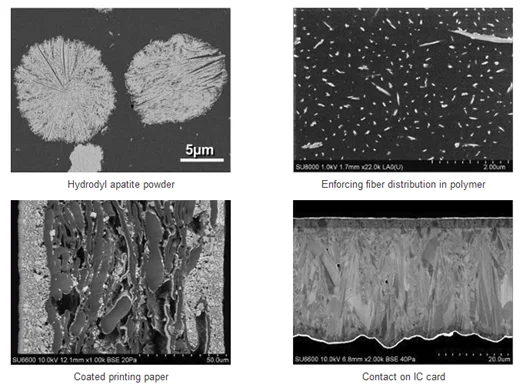

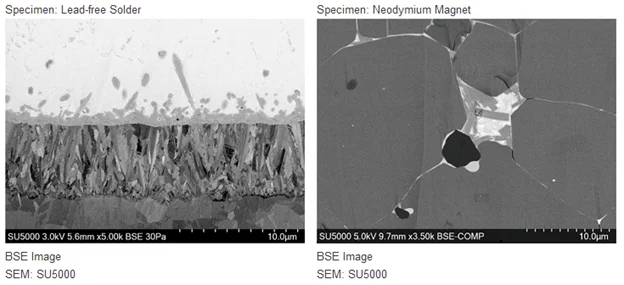

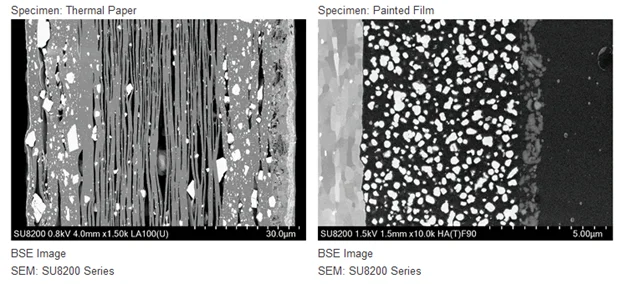

The IM4000Plus broad Ar+ ion milling system (BIB) from Hitachi is suitable for cross-sectioning or polishing of hard, soft, porous, composite and heat sensitive materials and delivers perfect results.

Reliable High-Performance Milling

-

High current Ar+ beam allows quick and consistent cross-sectioning

-

Stable low kV (<1 kV) capability for sensitive materials

-

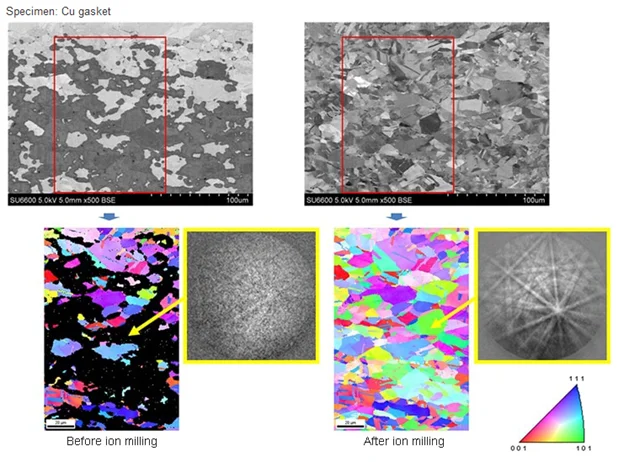

Suitable for final polishing, for example, for EBSD, utilizing low-angle milling (FlatMilling), or for contrasting by high-angle milling (relief milling) in just a few minutes

Image Credit: Hitachi High-Tech Europe

Easy Specimen Handling

-

Milling position can be readjusted at any time without remounting the specimen

-

Ex-situ alignment of mask and specimen makes setup fast and easy

-

Resin-embedded samples of up to 50 mm in diameter and 25 mm in height can be loaded for ultimate polishing

Simple Operation and Maintenance

-

Minimum and easy parameter settings for all types of applications or samples

-

Single ion beam gun allows easy setup and maintenance

-

Uniform, high-intensity ion beam throughout the complete voltage range, with separate acceleration voltages and ionization

Easy End-Point Detection

-

Real-time milling can be observed with the stereomicroscope

Extendibility

-

Cryo cooling can be added for heat sensitive materials

-

Vacuum transfer can be added for oxidation sensitive samples

Image Credit: Hitachi High-Tech Europe

Image Credit: Hitachi High-Tech Europe

Image Credit: Hitachi High-Tech Europe

Image Credit: Hitachi High-Tech Europe

Image Credit: Hitachi High-Tech Europe