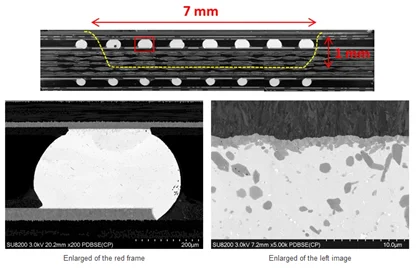

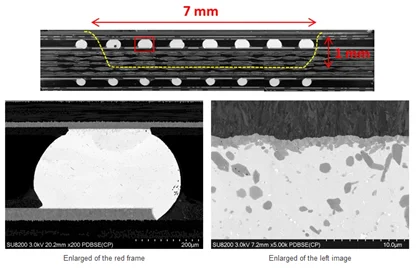

The sophisticated IM5000Ar ion beam milling system from Hitachi can be used to prepare customized cross-sections measuring up to 10 mm wide. It also enhances pre-polished surfaces of samples that are often hard to prepare through conventional means (such as polishing, grinding and cutting).

Processing Performance

- Custom width uniform cross-sections measuring up to 10 mm wide can be processed

- Final polishing, for example, for EBSD, utilizing low angle milling (FlatMilling), or for contrasting by high angle milling (relief milling), in just a few minutes

- A single powerful ion beam gun allows high milling speed

- Constant ion beam emission from sub-1 kV accelerating voltage

- Supports fine-surface polishing of sensitive materials

Image Credit: Hitachi High-Tech Europe

Easy Sample Handling

- Milling position can be readjusted at all times without remounting the specimen

- Ex-situ alignment of mask and cross-sectioning range makes setup fast and easy

- Resin-embedded samples of up to 25 mm in height and 50 mm in diameter can be loaded for ultimate polishing

Simple Operation

- Easy maintenance and setup with a single ion beam gun

- Single button push to initiate a process

- Programmable multi-step processes

Extendability

- Cryo cooling allows cross-sections on heat sensitive materials

- Multi-position auto-processing, recipe management and workflow creation

- Treating oxidation sensitive sample (such as LiB electrodes) without making contact with air

Link to our supplier